Vol 3 No 1 (2021)

Research Article

Composite materials were prepared with palygorskite-gypsum associated ore, modified corn starch and corn stalk as raw materials, glycerin as plasticizer, ammonium persulfate as initiator, KH-560 as organosilane coupling agent and linseed gum as adhesion promoter. Tensile strength, flexural resistance and compressive strength were used as the evaluation criteria to investigate the optimal ratio of composite material. The effect of the content of palygorskite-gypsum associated ore and glycerol, the ratio of modified starch to corn stalk as well as the ratio of initiator to coupling agent on the mechanical properties was investigated. Composite materials were characterized by means of SEM, FT-IR, XRD and TG/DTG. The impact on the environment of composite material was evaluated via measuring the degradation and bacteriostatic properties. The degradation rate of the composite reached 52.7% when the degradation time was 42 d and the composite had a good antibacterial property.

The corrosion behaviors of six Fe-19Ni-13/21Cr-xAl (x = 0, 2, 6 at. %) alloys in 10% CH4/H2 at 800oC were investigated. 2 at. % Al did not affect the corrosion resistance obviously, while 6 at. % Al reduced the carbon attack completely for Fe-19Ni-13Cr-6Al but was still insufficient to form protective alumina scales for alloys with 21 at. % Cr. An increase of Cr content changed the appearance of the internal carburization zone under the optical microscope. Stability diagrams of M-C-O system(M= Cr, Fe)were established to estimate the diffusion paths of carbon in the alloys.

In the present work, pure BaTiO3, pure Ni0.6Zn0.4Fe2O4 and (1-x)BaTiO3-xNi0.6Zn0.4Fe2O4 (where x = 0.15, 0.25 & 0.35) multiferroic composites were synthesized through solid-state sintering scheme. Structural, microstructural, ferroelectric, and ferromagnetic analysis was performed. Both tetragonal perovskite phase (for BaTiO3 ferroelectric phase) and cubic spinel ferrite phase (for Ni0.6Zn0.4Fe2O4 ferromagnetic phase) were simultaneously presented within each composite. The ferrite phase exhibited a smaller crystallite size compared to the ferroelectric phase. All of the composites demonstrated homogenous irregular-shaped grains. The measured average grain size for 0.85BaTiO3-0.15Ni0.6Zn0.4Fe2O4, 0.75BaTiO3-0.25Ni0.6Zn0.4Fe2O4, 0.65BaTiO3-0.35Ni0.6Zn0.4Fe2O4 were 364.14 nm, 378.46 nm and 351.62nm, whereas the density values were 3.04g/cm3, 3.20g/cm3 and 3.13 g/cm3 for x = 0.35, 0.25, 0.15 respectively. However, the heterogenous microstructure was observed for all of the compositions. The composites exhibited an oval-shaped lossy capacitor hysteresis loop. However, 0.75BaTiO3-0.25Ni0.6Zn0.4Fe2O4 composite showed the highest remnant polarization (11.613 μC/cm2) and coercive field value (1.526 kV/cm), ensuring its usability for switching applications. In addition, 0.75BaTiO3-0.25Ni0.6Zn0.4Fe2O4 also exhibited the maximum saturation (Ms= 1.732 emu/g) and remnant magnetization (Mr= 0.025 emu/g) among the composites. Nevertheless, all of the composites derived 'wasp-waisted' hysteresis loops due to the presence of either superparamagnetic (SPM) particles or a mixer of a single domain (SD) and superparamagnetic particles.

Review

Hybrid composites utilize more than one kind of strands within the same matrix to urge the synergistic impact of both fibers' properties on composites' general properties. Hybridization can be performed from artificial, natural, and a combination of both fibers. The constituent filaments can be altered in numerous ways, driving to the variety in composite properties. Partial substitution of glass fiber with natural ones offers an advantage compared with glass fiber composites while permitting to obtain a mechanical performance higher than using pure natural fiber composites. Recently, researchers are tending towards the development of hybrid composites which will provide good static properties. In this context, a concise review has been done on the recent developments of natural/glass fiber-reinforced composites made by hand lay-up method. It includes a survey of the past research already available involving the hybrid composites and the effect of various parameters on composites' performance studied by various researchers.

Commentary

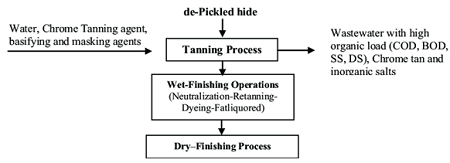

Tanning is the process of converting the raw skin and hides from different animals into a sustainable and manageable material called leather. Leather making is a very long process and consists of many different chemical and mechanical process steps. The most important step of the whole leather making process is the tanning step, which is performed commonly either by vegetable or mineral tanning. More than 85-90% of the leather making is performed by chrome tanning, which is the most common type of mineral tanning currently applied.

Haifeng Tian, Peng Gao, Haizhou Tian, Fei Zha, Zengjun Wang, Xiaojun Guo, Xiaohua Tang, Yue Chang

Haifeng Tian, Peng Gao, Haizhou Tian, Fei Zha, Zengjun Wang, Xiaojun Guo, Xiaohua Tang, Yue Chang